Problem driven innovation design strategies research for product manufacturing process

Constructing problem elements

Nowadays, innovation-driven development has become a new focus of international progress, and practice has proven that “design innovation” is a crucial pathway for innovation-driven development. Essentially, design is an activity that guides the current state towards a better direction, continuously discovering and solving problems throughout the manufacturing process to ultimately achieve innovation goals. However, problem discovery is the starting point for problem-solving and forms the foundation of innovation. Products continuously evolve through the iterative process of discovering and solving problems. The process is crucial for product innovation, as it encompasses the methods, technologies, and procedures involved in product manufacturing, directly affecting the product’s quality, cost, and market competitiveness. Therefore, how to discover issues in the product manufacturing process and clarify the problems that need to be addressed is crucial.

In the fields of education and psychology, Antonijević pointed out that problems are cognitive barriers that prevent the realization of goals52. It refers to aspects of the current state that are less than ideal and unresolved, or unexpected developments. In the context of product manufacturing process issues, it often refers to cases where the product produced by the current manufacturing process does not meet the design requirements. Problems comprise many elements; currently, psychologists categorize these elements into three parts: given, goals, and obstacles. The given describes the known conditions of the problem at its initial state; goals summarize the conclusions at the problem’s target state; and obstacles are the main reasons that prevent achieving the target state, requiring specific thinking methods to find accurate answers. Building on these three parts, some scholars propose that the elements of a problem include the overall goal, initial conditions, methods of changing states, and obstacles.

Problems arise due to dissatisfaction of manufacturing process personnel with the products manufactured using the current manufacturing process scheme. Based on the research by the aforementioned scholars on the elements of a problem, the elements of a problem in the product manufacturing process include PT (Product Targets), KC (Known Conditions), OT (Opportunity Types), and Ob (Obstacles), as shown in Eq. (1):

$$\:PE=\{PT,KC,OT,Ob\}$$

(1)

PE represents problem elements, PT stands for product targets, which refers to the desired state of a specific function in the product. KC denotes Known Conditions, referring to the current situation related to the product manufacturing process. OT signifies opportunity types, indicating the type of opportunity associated with the current problem, which is relevant for subsequent problem-solving. Different opportunity types correspond to different problem-solving strategies. Ob refers to Obstacles, which are the main reasons that affect the product’s ability to achieve the target during the manufacturing process.

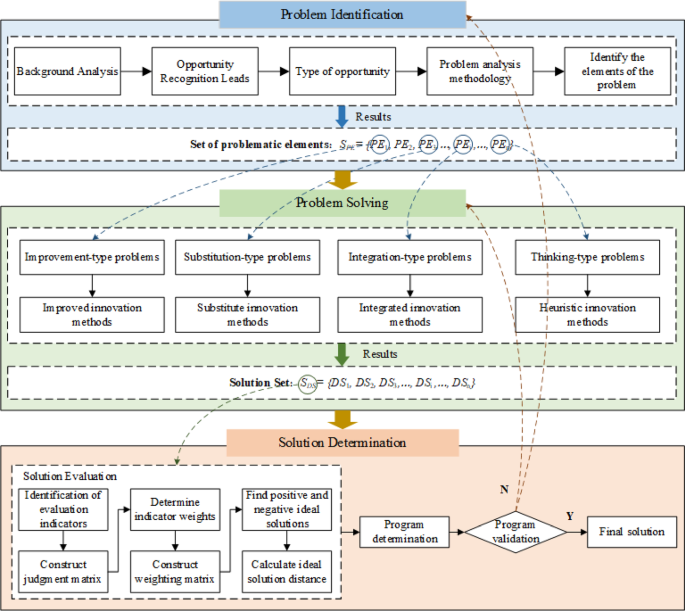

The process of determining problem elements is essentially the process of problem discovery. In this study, problems are identified through the construction of a problem guide set, leading to the development of problem elements. The main process is illustrated in (Fig. 2). Specifically, opportunity identification is guided by analyzing the problem background, which includes two main aspects: the product-related background and the product manufacturing process. Since the product manufacturing process directly affects the product’s design, quality, cost, and market competitiveness, the root causes of many issues often lie within the product manufacturing process. Therefore, this study focuses primarily on the product manufacturing process for determining problem elements, with supplementary analysis of the product-related background to identify product innovation opportunities. Opportunity types are further determined, and different problem analysis methods are employed for each opportunity type to identify the final problem elements.

Process for determining problem elements.

Based on the group’s previous related research53,54, this study categorizes the types of opportunities into personnel-based opportunities, technology-based opportunities, all-new-based opportunities, and recognition-based opportunities. Personnel-based opportunities arise from requests for improvements made by process personnel regarding existing issues in the product manufacturing process. These opportunities are explicit and fundamental, and are generally obtained through methods such as causal chain analysis and surveys. Technology-based opportunities occur when process personnel are dissatisfied with existing product processes but do not know how to improve them. These opportunities are implicit and challenging to analyze, requiring personnel to improve processes from a principle-based perspective, relying on technological advancements or technology transfer from other fields. Methods such as QFD and first principles are commonly used. All-new-based opportunities involve innovative or disruptive process innovations driven by technological development. Essentially, these are new demands that often arise from technological advancements or trends. These opportunities are usually implicit, deep, and broad, and can typically be identified through methods such as brainstorming and trend analysis. Recognition-based opportunities involve process requirements related to the appearance and significance of the product. These opportunities are explicit, vague, and personalized, and such needs are often difficult to fulfill. They can typically be identified through methods such as observational analysis and ethnography.

Through the above problem discovery steps and methods, a problem elements set \(\:{S}_{PE}\) can be formed. Subsequently, problem-solving strategies are guided based on the issues in the element set.

$$\:{S}_{PE}=\{{PE}_{1},{PE}_{2},{PE}_{3},\dots\:{PE}_{i},\:\dots\:,{PE}_{n}\}$$

(2)

\(\:{PE}_{i}\) represents the i-th problem element in the product elements set.

Problem solving based on innovation strategies

After identifying the problem elements in the product manufacturing process, the next step is to address the specific problem elements within the problem element set. Due to the abundance of innovation methods available, it is challenging for process engineers in enterprises to select the appropriate methods. Furthermore, with the continuous evolution and increasing demands of the manufacturing industry, low innovation efficiency has become a prominent issue in the manufacturing process innovation design. The main challenge now is to apply different innovation methods to various problems and effectively enhance problem-solving efficiency. Therefore, this section proposes a problem-solving method based on innovation strategies to assist process engineers in solving current issues in product manufacturing process.

Analysis of commonly used innovation methods

Innovation methods are strategies and tools developed based on innovation practices to assist in creative thinking. They are systematic descriptions and norms of the innovation environment, content, goals, processes, and steps, representing a structured summary and formalization of effective and mature creative thinking. Innovation methods can guide process personnel in innovation. Developed countries such as those in Europe and America place significant emphasis on these methods, while domestic research started relatively late compared to abroad, with studies gradually beginning in the 1960s. According to statistics, researchers have developed over 300 innovation methods to support product innovation design, with dozens being commonly used55. This study analyzes commonly used innovation methods from four aspects: supporting technologies, supporting information, supporting processes, and method types.

Study have shown that commonly used innovation methods are primarily based on seven supporting technologies: Adaptation/Induction/Organization (1), Randomness (2), Aggregation (3), Systematic Approach (4), Directionality (5), Directed Evolution (6), and Innovation Knowledge Base (7)56. The support of innovation methods for information is mainly reflected in their ability to provide stimulating information to process personnel during the process of innovation design. Based on the source and mode of information generation, it can be categorized into four types: External Guidance, Internal Guidance, Internal Random, and External Random57, as shown in (Fig. 3a). The innovation process is generally divided into three stages: identifying the problem, generating innovation ideas, and determining the solution with innovation potential. This process is further detailed into six steps: Problem Analysis (I), Problem Identification (II), Concept Solving (III), Domain Solving (IV), Solution Evaluation (V), and Combinatorial Optimization (VI)58,59, as shown in (Fig. 3b).

(a) Segmentation of information (b) Design process steps.

Research on commonly used innovation methods currently focuses on three aspects: Thinking flow type (X), thinking operation type (Y), and thinking procedure type (Z). In the application of specific innovation methods, they function in three areas: Innovation Analysis (①), Innovation Thinking (②), and Innovation Motivation (③)60. Innovation Analysis primarily assists personnel process in defining innovation problems and identifying innovation opportunities and resources. Innovation Thinking helps process personnel explore the solution space to obtain suitable solutions with innovation potential. Innovation Motivation involves providing stimulating information to process personnel, thereby inspiring innovation ideas.

-

(1)

Research on innovation methods primarily focused on thinking flow is mainly represented by studies from some developed countries in Europe and America. This approach emphasizes the free flow of thought and views invention and creativity as inevitable results of imaginative, associative, insightful, and intuitive thinking activities. Methods proposed include brainstorming, checklists, morphological analysis, and biomimicry.

-

(2)

Research on innovation methods focused on thinking operation is primarily represented by studies from Japan. This approach leans towards the practical operation of thought and views invention and creativity as inevitable results of the organic interaction between logical and non-logical thinking, achieving breakthroughs in thinking. Methods proposed include the KJ method, Six Thinking Hats, and mind mapping.

-

(3)

Research on innovation methods focused on thinking procedure is primarily represented by studies from the former Soviet Union. This approach views invention and creativity as inevitable results of organized thinking activities based on objective laws of cognition, achieved through specific procedures rather than by chance. Methods proposed include TRIZ theory, systematic innovation thinking techniques, creative templates, and the FBS method.

Based on preliminary laboratory research, various commonly used innovation methods are listed as shown in (Appendix Table 1)61. A comparative analysis of the application characteristics of these methods from the aspects is conducted to lay the methodological foundation for subsequent application of strategy methods.

Problem solving methods

In order to avoid as much as possible the blindness that may occur when designers are looking for solutions to design problems, this paper develops the corresponding problem types for the types of opportunities on the basis of the group’s previous related research53,54. To address issues of different types of opportunity, this study first defines corresponding problem types, namely improvement-type problems, substitution-type problems, integration-type problems, and inspiration-type problems. Furthermore, different problem-solving methods corresponding to these problem types are proposed. These methods, supported by problem-solving strategies and relevant knowledge services, aim to stimulate creative thinking in process personnel, leading to strategic problem solving and generating solutions. The specific strategic problem-solving model is shown in (Fig. 4).

Problem solving methodology process.

As shown in Fig. 4, four problem-solving methods are proposed: Improved innovation methods, Substitute innovation methods, integrated innovation methods, and Heuristic innovation methods to support problem-solving.

Improved innovation methods are suitable for improvement-type problems, primarily addressing conflicts in existing technical systems. They originate from specific improvement needs proposed by process personnel for existing manufacturing process schemes and often use TRIZ theory and creative templates for problem-solving. Process personnel can choose method based on specific improvement-type problems to design.

Substitute innovation methods are suitable for substitution-type problems, mainly when the improvement of the existing technical system has reached its limit. These strategies originate from the dissatisfaction of process personnel with existing manufacturing process schemes without knowing how to improve them. They often use FBS and first principles for problem-solving. For example, when using FBS for innovation design, the behavior and structure corresponding to the product function can be mapped to assist process personnel in innovating the behavior or structure in the manufacturing process scheme.

Integrated innovation methods are suitable for integration-type problems, mainly targeting new or disruptive process schemes characterized by the combination of multiple technologies. These strategies arise from new demands, technological advancements, or development trends in the process. Combination innovation starts with the design goals, analyzes the existing system parameters and manufacturing process scheme components, and uses analogical thinking to apply manufacturing process schemes from other fields to the current manufacturing process. By comparing and combining the corresponding manufacturing process schemes, product innovation schemes are generated.

Heuristic innovation methods are suitable for thinking-type problems, mainly for manufacturing process scheme problems without specific goals. These are characterized by non-logical thinking innovation, achieved by stimulating the thinking of process personnel. This strategy often uses brainstorming and mind mapping for problem-solving. When facing such design problems, the strategy pushes a large amount of information related or unrelated to the manufacturing process design problem to the process personnel, forcing them to make associations and generate ideas.

This process mainly involves the strategic problem-solving of product manufacturing process problem elements to obtain manufacturing process innovation schemes. Subsequently, the manufacturing process innovation scheme set is evaluated and validated to determine the final product manufacturing process scheme.

Defining solutions with innovation potential

After problem-solving, multiple product manufacturing process design solutions are obtained. The optimal solution among them is usually determined through a solution evaluation method. Solution evaluation is a method where process personnel analyze, compare, and assess the set of solutions, helping them to select the optimal solution from the many available, ensuring that the chosen solution can address the current issues in the process engineering. The chosen solution is then subjected to validation; if the validation is successful, the final solution is determined. If other issues are found during the validation phase or if the problem-solving is incomplete, the process iterates back to problem-solving. This cycle is repeated until the solution passes validation and the final solution is determined. The solution determination process is shown in (Fig. 5).

The process of solution determination.

In this paper, a solution evaluation method based on AHP and TOPSIS is used. The Analytic Hierarchy Process (AHP) was first proposed by American scholar Saaty in 1971 and is a decision-making method that combines qualitative and quantitative analysis. This method has a scientific decision-making structure and systematic nature, which can effectively assist process personnel in making decisions. The Technique for order of preference by similarity to ideal solution (TOPSIS) is often used in multi-objective decision-making manufacturing processes, allowing for the comparison of the advantages and disadvantages of various solutions to obtain the optimal solution. The TOPSIS analysis method is a multi-attribute decision-making technique. The basic concept of this method is that the selected alternative should have the shortest distance to the positive ideal solution and the farthest distance from the negative ideal solution62. In the TOPSIS analysis method, the schemes of the evaluation objects are converted into a matrix of attribute values, with each row representing an evaluation object and each column representing an attribute. By calculating the distance between each scheme and the positive and negative ideal solutions, the degree of superiority of each scheme is evaluated, and the optimal scheme is selected. Due to its strong objectivity and operability, this method is widely used in the analysis of corporate competitiveness. However, because the TOPSIS analysis method cannot determine the weights of each evaluation index, weights need to be assigned before evaluation. Therefore, in this paper, the two methods are combined by introducing the AHP method before the TOPSIS analysis method to determine the weights of each evaluation index, making the evaluation more scientific and effective. The process of the solution evaluation method based on AHP and TOPSIS is shown in (Fig. 6).

Methodological flow of solution evaluation based on AHP and TOPSIS methods.

In this study, the AHP method is first used to determine weights. A decision expert group \(\:G=\left\{{G}_{1},{G}_{2},\dots\:,{G}_{n}\right\}\) composed of \(\:N\) experts evaluate each evaluation index. According to Table 2, the experts compare the \(\:n\) evaluation indexes pairwise to establish a judgment matrix. By applying the judgment matrix, the weight vector is obtained, and the weight of each evaluation index is calculated.

$$w_{i} = \frac{1}{n}\sum\limits_{{j = 1}}^{n} {\frac{{a_{{ij}} }}{{\sum\limits_{{i = 1}}^{n} {a_{{ij}} } }}} (i,j = 1,2,3, \ldots ,n)$$

(3)

To ensure data validity, the weight calculation results need to pass consistency testing, which is calculated using Formula (4).

$${C_R}=\frac{{{C_I}}}{{{R_I}}}$$

(4)

In the formula, \({C_I}\) represents the consistency index, \({R_I}\) represents the random consistency index, with values shown in (Table 3); \({C_R}\)represents the consistency ratio. When \({C_R}\) = 0, it indicates perfect consistency; when \({C_R}\) is close to 0, it indicates satisfactory consistency; as increases, the level of inconsistency becomes more severe. When \({C_R}\) ≤ 0.1, the judgment matrix is considered to have passed the consistency check, and the weights of the evaluation indicators are deemed to be acceptable.

Next, the TOPSIS analysis method is used for scheme evaluation. Let there be M evaluation schemes, forming the scheme set \(\:P=\{{P}_{1},{P}_{2},\dots\:,{P}_{m}\}\); and N evaluation criteria, forming the criteria set \(\:I=\{{I}_{1},{I}_{2},\dots\:,{I}_{n}\}\). The evaluation criteria feature matrix is63

$$\user2{A} = \left[ {\begin{array}{*{20}c} {\begin{array}{*{20}c} {\begin{array}{*{20}c} {a_{{00}} } \\ {a_{{ij}} } \\ \end{array} } & {\begin{array}{*{20}c} {a_{{01}} } \\ {a_{{ij}} } \\ \end{array} } \\ \end{array} } & \cdots & {\begin{array}{*{20}c} {a_{{0j}} } \\ {a_{{ij}} } \\ \end{array} } \\ \vdots & \ddots & \vdots \\ {\begin{array}{*{20}c} {a_{{ij}} } & {a_{{ij}} } \\ \end{array} } & \cdots & {a_{{mn}} } \\ \end{array} } \right]$$

(5)

Where, in Formula (5), \({a_{ij}}\) represents the score of the j-th evaluation index in the i-th alternative. Then, after standardizing the evaluation criteria feature matrix \(\:\varvec{A}\), the standardized matrix \(\:{\varvec{B}}_{ij}\) is obtained.

$${{\varvec{B}}_{ij}}=\frac{{{a_{ij}}}}{{\sqrt {\sum\limits_{{i=1}}^{m} {a_{{ij}}^{2}} } }}$$

(6)

After weighting, the weighted normalized matrix \(\:{\varvec{Z}}_{ij}\) is obtained:

$${{\varvec{Z}}_{ij}}={{\varvec{w}}_i}{{\varvec{B}}_{ij}}$$

(7)

Next, determine the positive and negative ideal solutions by letting:

$$u_{j}^{ + } = \max \{ u_{{1j}} ,u_{{2j}} , \ldots ,u_{{nj}} \} (j = 1,2, \ldots ,m)$$

(8)

$$u_{j}^{ – }=\hbox{min} \{ {u_{1j}},{u_{2j}}, \ldots ,{u_{nj}}\} (j=1,2, \ldots ,m)$$

(9)

The positive ideal solution is obtained as:

$${X^+}=(u_{1}^{+},u_{2}^{+}, \ldots ,u_{j}^{+})$$

(10)

The negative ideal solution is obtained as:

$${X^ – }=(u_{1}^{ – },u_{2}^{ – }, \ldots ,u_{j}^{ – })$$

(11)

Then, the distances of each solution from the positive and negative ideal solutions are calculated using formulas (12) and (13)64, respectively:

$$D_{i}^{+}=\sqrt {{{\sum\limits_{{j=1}}^{n} {({u_{ij}} – u_{j}^{+})} }^2}} (i=1,2,.,m)$$

(12)

$$D_{i}^{ – }=\sqrt {{{\sum\limits_{{j=1}}^{n} {({u_{ij}} – u_{j}^{ – })} }^2}} (i=1,2,.,m)$$

(13)

Finally, the evaluation score for each solution is calculated using formula (14):

$${S_i}=\frac{{D_{i}^{ – }}}{{D_{i}^{+}+D_{i}^{ – }}}$$

(14)

Solutions are ranked based on their evaluation scores \(\:{S}_{i}\). A higher score indicates that the solution better meets the needs of the process personnel, whereas a lower score indicates less satisfaction. The solution with the highest evaluation score is selected as the final solution. After selecting the highest-scoring solution through the evaluation method, further experimental validation is conducted. Experimental simulations are used to analyze the results and determine the feasibility of the solution. If the experimental validation shows that the solution does not meet the product manufacturing requirements, the solution is iteratively redesigned, and the problem is redefined or re-solved. After obtaining the revised solution, it is validated again through experiments to determine its feasibility. If experimental validation meets the requirements, the solution is confirmed as the final one.

link